High efficiency two stage conpounding extruder for PVC EVA PE material has excellent mixing performence, good self-cleaning performance and flexible modular configuration characteristics which make them suitable for processing different types of materials. And this machine has been abroad applied to PVC cable material, XLPE material, low smoke free halogen cables, shield material,chemical crosslinking cable material, wood plastic, a wide range of uses.

models of High efficiency two stage conpounding extruder for PVC EVA PE material:

|

Parameter

Model

|

Main frame

|

Motor Power(kw)

|

Rotate speed(rpm)

|

| GSJ-50/100 |

GS-50twin screw extruder |

37-55 |

500-600 |

| GSD-100single screw extruder |

22-45 |

60-90 |

| GSJ-65/150 |

GS-65 twin screw extruder |

55-75 |

500-600 |

| GSD-150 single screw extruder |

45-55 |

60-90 |

| GSJ-75/180 |

GS-75 twin screw extruder |

75-132 |

500-600 |

| GSD-180 single screw extruder |

75-90 |

60-90 |

| GSJ-95/200 |

GS-95 twin screw extruder |

250-315 |

400-500 |

| GSD-200 single screw extruder |

90-132 |

60-90 |

High efficiency two stage conpounding extruder for PVC EVA PE material can be followed with four main kinds of pelletizing system:

1. Water /fan cooling strand pelletizing system

2. Water ring hot- face cutting system

3. Under-water pellet system

4. Eccentric water-spray pelletizing system

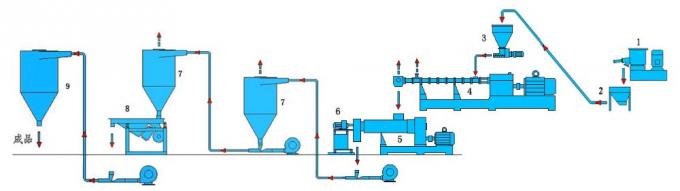

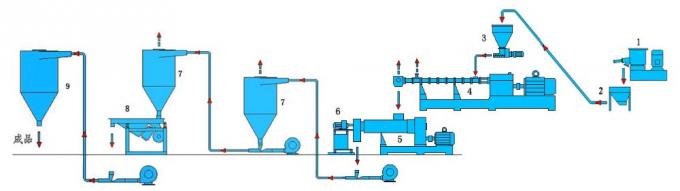

Air-cooling hot-face pelletizer

1. High speed mixer 2.Screw loader 3.feeder 4. twin screw extruder 5.Single screw extruder

6.air cooling hot face sutter 7. Cyclone 8. Vibrating sieve 9.storage silo